Baby & Kids'

Wear Production

With The Finest

Quality.

About Lumex

Lumex is one of the oldest companies manufacturing baby clothes in the MENA region and was established in 1939. Our manufacturing plant is designed on an entire surface of 7500 m2 in the 10th of Ramadan city industrial area, Egypt with a simple but robust vision; When you think about kids, you think Lumex.

Lumex Journey

1st Generation

The first factory was built in Downtown, Cairo

2nd Generation

Expanded in one of the main industrial zones in Egypt, the 10th of Ramadan city, Cairo

3rd Generation

Opening a new production line for children aged 4-10 years, launched with the brand name NINOS

4th Generation

Re-branded the whole identity, aiming at the global market. Growth in progress...

Lumex Manufacturing Services

Lumex paves the way to designers & textile players to manufacture their designs in Lumex’s factory with the same apparel production process as ours.

Fabric Check

When the fabric is received, it is laid down for 24h, checked thoroughly for any fault, and fabric defects go back to the textile manufacturer.

Lay, Pattern, and Cut

We spread the fabric through a computer-controlled system in parallel with the pattern created in the sampling stage to calculate the fabric consumption, then, the cutting operations are carried out.

Now We Sew

Sewing is done after the cut pieces are bundled according to style, size, and color. Quality assurance is performed at the end of the sewing line to ensure that no manufacturing defects exist.

Embroidery and Screen Print

Embroidery is performed using automated equipment on multiple fabrics. As for screen printing, we use cutting-edge techniques with steadfast, reliable, and consistent ink.

Double-Check

Quality control procedures are operated at all the production stages, including pre-, during, and post-production levels.

Fuse and Press

After the garment is fully sewn and assembled, the fusing and pressing section begins, it has the greatest influence on the finished look of each item.

Sustainably Pack and Ship

Now the garments are folded, tagged, sized, and packaged according to each line's specifications.

Diversity of Machines

The machines’ diversity covers all the functions for production; single stitch, double stitch, Overlock, Ocerlock upper feed, Lock stitch, Chain stitch, long arm double chain stitch, Zigzag lock stitch, Zigzag double stitch, Button, Buttonhole, Snap press, Embroidery 8 head, embroidery 12 head, Silk screen, printing table 36 meter with dryers

Number of machines

We operate with more than 150 machines with high-quality brands and high-end functions.

Minimum order quantities per style and lead time

We start from 450 pieces per style and color reaching the target for each patch requirement.

Lumex Partners

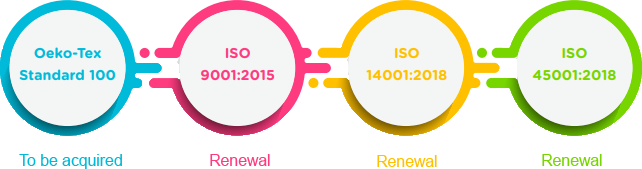

Certificates

Lumex is certified on different levels, some certificates will be acquired by March 2023 and others are in the renewal phase.

Lumex Ecosystem

Lumex ecosystem is rooted to include all the business and textile market players, starting from the education to the internal staff, setting employees wellbeing policies, opening opportunities for internships. And developing the manufacturing process by following the latest research and trends with sustainability plan 2027, offering apparel production services for small and medium companies, building long-term partnerships with the retailers, and impacting the community with CSR projects.

Education & development are the baselines at Lumex, from there all is built. Lumex vocational school for sewing and tailoring for teaching the new staff the apparel manufacturing techniques while providing the old employees with the best practices and trends of the market to aquire new or improve existing skills.

We understand how safe working environment can support employees mentally and increase the productivity level along with loyalty in any company, and as we care about business profit, we do care about our people’s benefits.

- Social solidarity program

- Diversity & inclusion policy

- Health Check-up

- Research & development

- Lumex Sustainability Plan 2027

- Internships

- Community impact & CSR Projects

In the lead-up to COP27 United Nations Climate Change Conference, we are taking robust steps towards sustainability in collaboration with the Ministry of Environment:

Material & Fabrics

- Increase the percentage of using organic cotton

- Recyclable fabrics such as Polyester

- Use eco-textile dyes

Packaging

- Replace the plastic with a cardboard clothes hunger

- Use biodegradable plastic bags

Lumex offers apparel production services for the local and small business in the market for manufacturing their designs in Lumex’s factory

Lumex approached a well-defined business plan to design its retailing network either on B2B or B2C level. During the last 60 years, Lumex established hundereds of partnerships to distribute its products in stores.